Ensuring Food Safety: A Comprehensive Guide to Successful Audit Preparation

The Importance of Audits in Ensuring Food Safety: A Guide to Successful Preparation

Audits play a vital role in upholding food safety systems and obtaining certifications that demonstrate adherence to best practices, ensuring the production of safe, high-quality foods. These audits are essential in creating transparency within the supply chain for enhancing food safety while promoting continuous improvement and upholding your hygiene standards. However, preparing for an audit is no small task. It requires the team to adopt new ways of working, such as documenting actions taken, obtaining additional training, and fostering better communication between departments. The ultimate goal is to foster collaboration, follow defined processes and improve understanding of requirements at all levels. When done systematically, this process not only ensures compliance but also helps to cultivate a culture of food safety, making the team audit-ready every day.

As critical as audits are, it's essential to address why some organisations may struggle to perform well during these evaluations. Factors such as a lack of management commitment, resource challenges, and inexperience within the team can contribute to audit difficulties. However, overcoming these initial hurdles is only the first step. A mindset shift is required, with teams adopting an auditor's perspective and honing their preparation skills.

To help you and your team succeed in your next audit, here is a list of Do's and Don'ts to consider:

Do's:

Be Prepared throughout the Year:

Start planning well in advance to implement and enhance programs, train the team and identify and address non-conformances before the audit.

Cross-functional team support and readiness:

Involve all key stakeholders to help develop, implement and reinforce policies, procedures and plans. Obtain buy-in from the team along the way.

Follow your procedures and verify their effectiveness:

Conduct inspections and internal audits to ensure the programs are functioning as intended, addressing any non-conformances proactively.

Provide Objective Evidence with clear and concise answers to questions:

Be prepared to provide documentation, records and detailed answers to help auditors determine conformity.

Be Organised:

Ensure that all necessary documents and records are readily available and retrieved promptly during the audit.

Team understands the Code as well as the Auditor:

Train all team members to understand the food safety requirements to foster better adoption and ongoing implementation.

Develop an Agenda in Collaboration with the auditor:

Work collaboratively with the auditor to ensure they understand the site's specific circumstances, which will lead to a more successful flow of the audit.

Be Positive and be open to the Auditors Findings:

Approach the audit with a positive mindset, remain open to the auditor's questions, and provide objective evidence to support any disagreements.

Show management commitment and leadership throughout the audit:

Ensure management representation and engagement throughout the audit, including participation in opening and closing meetings.

Focus on Continuous Improvement:

Embrace a mindset of continuous improvement and robust change management processes to achieve your audit goals.

Don'ts:

Wait to the last minute to prepare for the audit:

Procrastination can lead to incomplete preparations and lack of time for necessary improvements.

Have a team of one or just the technical team:

Success requires the involvement of all relevant stakeholders; a single person or technical team may not be sufficient.

Let the auditor find issues that the team could have found proactively:

Be proactive in addressing potential non-conformances before the audit.

Be Defensive or answer with just closed responses:

Provide detailed answers and objective evidence to help auditors assess conformity.

Documents and Records are not readily available:

Organise and make all required documents and records accessible during the audit.

Lack of training of the team and internal audits:

Train the entire team and conduct internal audits to ensure everyone understands and follows the food safety requirements.

Allowing the auditor to drive the Agenda:

Collaborate with the auditor to ensure the audit agenda considers the site's specific circumstances.

Be Combative with the auditor:

Maintain a positive attitude and remain open to the auditor's findings.

Having no management representation or engagement:

Ensure management is present and actively engaged throughout the audit process.

Have a mindset that creates complacency in programs and attitudes:

Foster a culture of continuous improvement to achieve audit success.

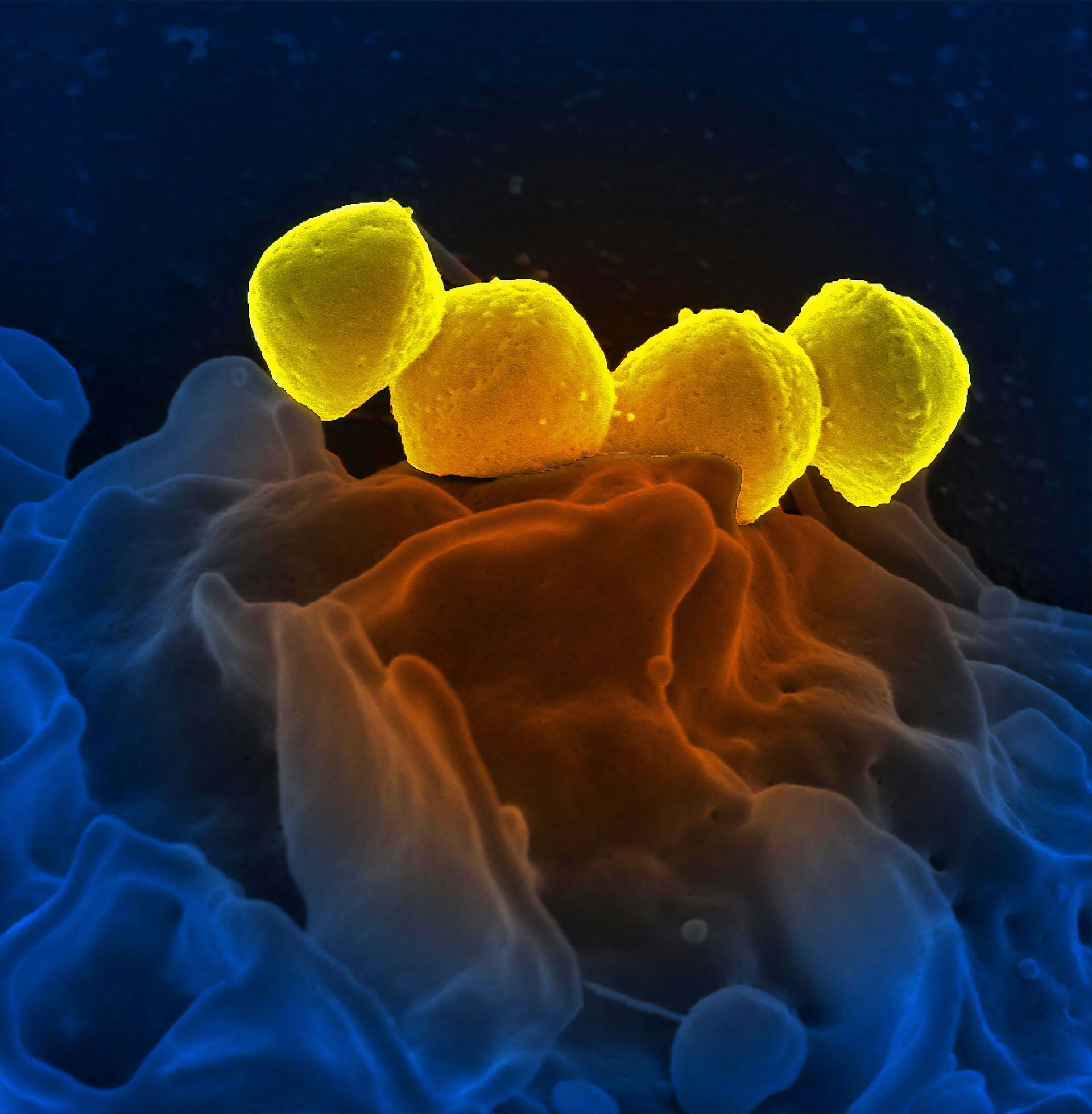

Don’t forget that whilst preparing for your audits, maintaining a clean and sanitary food preparation area is of the utmost importance to prevent contamination and uphold industry standards. By partnering with a professional cleaning service like

Hygiene Group, you can be sure that all of your equipment is kept up to industry standards.

In conclusion, audits are a crucial aspect of maintaining food safety standards and successful preparation requires both proactive planning and a positive, collaborative mindset. By adhering to the Do's and avoiding the Don'ts, you can significantly improve your audit performance and create a stronger food safety culture. Remember, the journey to challenge and grow your site's food safety program is ongoing and with commitment and teamwork you can be audit-ready every day!

Our team of experts is available at any time to help you keep your equipment cleaned up to the regulations stated by the authorities.

Contact us today by emailing enquiries@hygienestores.co.uk or calling 0121 458 5598!

Contact

enquiries@hygiene.co.uk

0121 451 3211

Mon-Fri 8am-5pm

Hygiene Group, 8 Castle Road,

Kings Norton Business Centre,

Kings Norton, Birmingham B30 3HZ

All Rights Reserved | Hygiene Group