Tips For Keeping Food Factory Equipment Clean & Up To Industry Standards

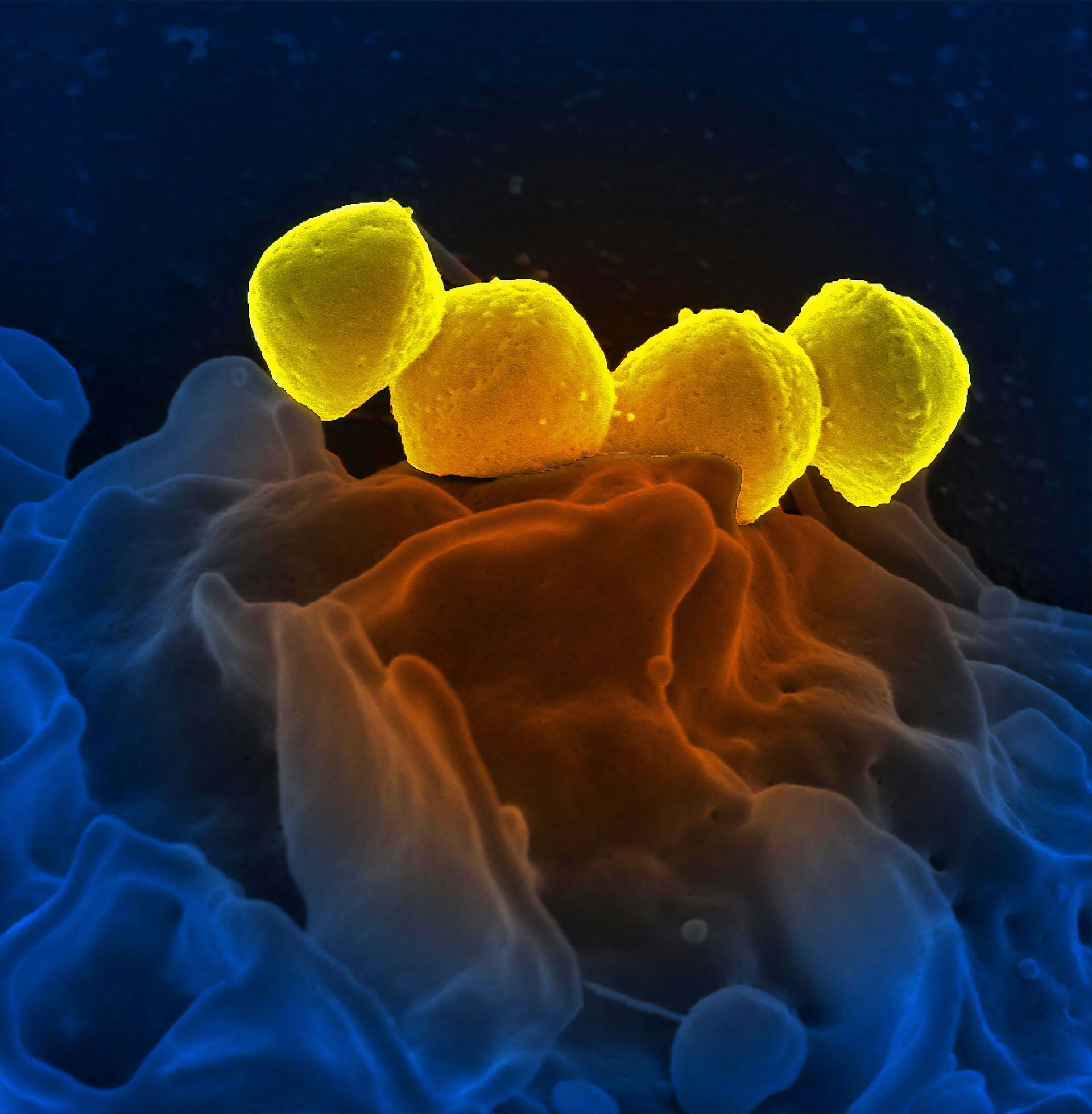

Food factories are often inspected by regulatory agencies and failure to meet hygiene and sanitation regulations can result in hefty fines. Maintaining a clean food production environment is critical for upholding industry hygiene standards and preventing the spread of bacteria and contamination. So, food factory equipment must be regularly cleaned and sanitised to protect the food supply and keep workers safe. To meet industry standards, it is essential to maintain clean equipment.

Here are a few tips to help you keep your factory equipment up to industry standards.

1. A well-organised cleaning schedule

A well-organised cleaning schedule is key to maintaining a clean and safe factory. All employees should be aware of the schedule and be trained in proper cleaning techniques. Keep a log of all cleaning activities to ensure that all areas of the factory are cleaned regularly. This log will help you keep track of what has been done and what still needs to be done. Having a schedule will also help you keep track of which areas need to be cleaned more often.

For example, if you know that the conveyor belt needs to be cleaned every week, you can make sure that it is done regularly. Additionally, a cleaning schedule will help you identify areas that may be difficult to clean or where bacteria could easily build up. This way, you can make sure that the cleaning is done when it is supposed to be and that there is no conflict with other work that needs to be done.

2. Using appropriate cleaners

Food factory equipment is a significant investment, so it's important to clean it regularly and appropriately to ensure its longevity. And it's important to use the right cleaners and detergents to avoid damaging the machinery. Some cleaners are too harsh and can cause corrosion or etching, while others may not be strong enough to remove tough stains.

It's important to find a cleaner that is specifically designed for the type of equipment you're cleaning. Otherwise, you run the risk of damaging your equipment and having to replace it sooner than necessary. The right cleaner will not only save you time and money in the long run, but it will also help to keep your equipment in top condition. If you are unsure of which cleaner will be the best for your equipment,

leave the cleaning to the experts so that you can get a high-quality cleaning job done with the correct cleaners so that your equipment is not damaged.

3. Regularly inspect and address the damage

Staying on top of routine maintenance schedules helps keep your food factory equipment running smoothly. This includes regularly inspecting and cleaning all filters, belts, and motors, as well as changing the oil in motors and hydraulic systems. By doing this, you can prevent small problems from turning into big ones that could lead to costly repairs or even a complete shutdown of your factory.

It's important to be vigilant about any signs of wear or damage and to repair or replace damaged equipment immediately. In addition, maintaining your equipment will help it to run more efficiently, saving you money on your energy bills. So make sure to add routine maintenance to your list of priorities to keep your food factory running like a well-oiled machine.

4. Allow only trained professionals to do the cleaning

Cleaning factory equipment is not a simple task. It requires specialised knowledge and skills, as well as the use of proper safety precautions. Consequently, it is important to ensure that only trained and experienced personnel are tasked with cleaning factory equipment. This will help to avoid accidents and ensure that the equipment is cleaned effectively.

Trained professionals know how to safely navigate these hazards and will take the necessary precautions to protect themselves and your equipment. In addition, they will have the proper cleaning products and tools to get the job done quickly and efficiently. As a result, you can rest assured that your equipment will be cleaned properly and that your food production will not be disrupted.

5. Follow the guidelines

Food factories are subject to a range of strict hygiene regulations. As a result, all equipment must be kept clean and free from contamination. However, cleaning machinery can be a delicate process, and it is important to follow the manufacturer's guidelines carefully to avoid causing damage. Depending on the type of machine, the cleaning process may vary.

For example, some pieces of equipment will need to be disassembled to clean the components separately, while others can be cleaned in place. It is also important to pay attention to the type of cleaning products that are used, as some chemicals can damage delicate parts of the machinery. By taking the time to read the manufacturer's instructions carefully, you can ensure that your equipment is cleaned correctly and safely. To meet industry standards, it is essential to maintain clean equipment and surfaces.

Maintaining a clean and sanitary food factory is of the utmost importance to prevent contamination and uphold industry standards. By partnering with a professional cleaning service like

Hygiene Group, you can be sure that all of your equipment is kept up to industry standards. We offer comprehensive cleaning services that will bring your factory up to industry standards quickly and affordably. Let us take care of everything so you can focus on what you do best – producing delicious food products!