Why Equipment Cleaning is Important in Manufacturing Plants

Why Equipment Cleaning is Important in Manufacturing Plants

The manufacturing process is an intensive and often dirty one. Much like any other workplace, a manufacturing plant needs to be clean and organised to run smoothly. However, because of the nature of the work that takes place in these facilities, it is especially important to make sure that all equipment is clean and free of contaminants.

In any manufacturing plant, the equipment is essential to day-to-day operations. This equipment needs to be kept clean and functioning properly to produce the products that are required. Failure to do so can lead to costly mistakes and product defects. That’s why equipment cleaning should be a top priority in every manufacturing plant.

Here are some reasons why equipment cleaning is important:

- To increase efficiency

A manufacturing plant is only as good as its equipment. Over time, dirt and debris will accumulate on machine surfaces and components, leading to decreased accuracy and performance in production. This can lead to decreased production, higher energy costs, and a less sanitary work environment.

To avoid this, it is important to have a comprehensive equipment cleaning schedule in place to clean all equipment in your factory. By following a regular equipment cleaning schedule, you can help reduce the chances of equipment failures and keep your facility running at peak efficiency. - To maintain safety standards

Unclean machines can lead to accidents. If dirt, grease, or other contaminants build up on moving parts or surfaces, it can create a hazardous environment that increases the risk for accidents and equipment break downs.

Equipment cleaning helps increase safety by reducing the risk of accidents. In some cases, specific pieces of equipment may require special cleaning solutions or procedures in order to ensure that they are clean and safe for use. By having professional equipment cleaning procedures for your factory's machines and equipment, you can help reduce the risk of accidents and keep your workforce safe. - To continue producing quality products

Debris and build ups on equipment surfaces can cause products to be defective, necessitating re-made items and lost time and money.

For a manufacturing plant to produce high-quality products, it is essential to keep the equipment clean. Equipment cleaning can be a time-consuming and challenging process, but it is worth the effort to avoid quality issues and maintain productivity. By keeping the equipment cleaned and free of debris, you help to ensure that the best possible quality products are being produced - those that meet customer expectations. - To prevent contamination

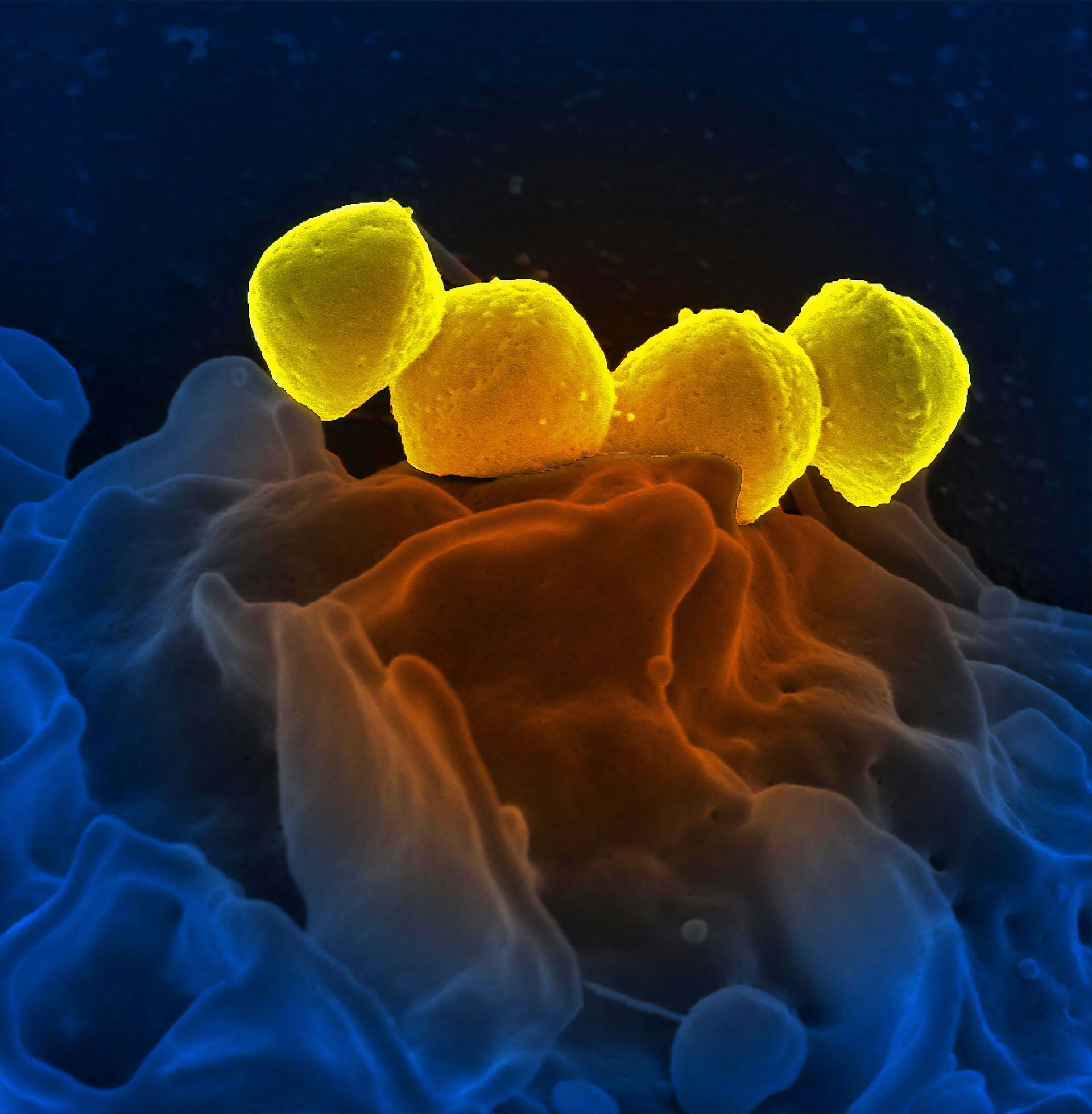

One of the most important reasons for equipment cleaning in manufacturing plants is to prevent product contamination. Contamination can come from a variety of sources, including unclean or greasy machines, dust, dirt, and other debris. All of these contaminants can have a negative impact on the quality of the product being produced.

The potential for contamination and foodborne illness outbreaks can be dramatically reduced by implementing a rigorous and effective equipment cleaning program. Not only does this remove dirt, grease, and debris, but it also prevents contaminants from building up and affecting the final product. - To extend equipment lifespan

Did you know that most equipment failures are caused by dirt and debris? Equipment cleaning intervals are necessary to remove all built-up debris, which can shorten the lifespan of costly machinery. By scheduling cleanings at regularly-determined intervals, you can reduce the amount of wear and tear it experiences, which can prolong its life and save you money in the long run. Regular equipment cleaning will also help identify potential problems before they turn into mechanical failures.

The best way to ensure that your manufacturing plant is running smoothly and producing high-quality products is by investing in a professional equipment cleaning service. At

Hygiene Group, we provide industry-leading equipment cleaning services that will help keep your machines clean and free of debris, ensuring that your products are of the highest quality.